What Really Drives an Automation System Upgrade?

Introduction:

I’m often drawn to the romance of aged wine and cheese — but technical systems don’t reward time in quite the same way. All system age, some gracefully, some less so – in all cases we are eventually confronted with the same question:

Is it time to upgrade?

Before we can truly answer this question, we need to ask a few others and ensure we understand the answers:

- What does “upgrade” really mean?

- What is really driving the desire to upgrade: Obsolescence, age related failures,

- Am I adding or reducing risk?

- Does the system need new functionality or are we adding complexity?

- Am I spending capital to save on operational budget?

- Is this perception or measurable technical reality?

- Could training, better understanding, strategic interventions and regular maintenance and inspections achieve the same outcome with less cost and risk?

- Is my system compliant?

- What options do I really have?

Context:

Whilst Automation is now commonplace in venues across the live entertainment sector, it is still considered young relative to its old timer colleagues of sound and lights and as such is less understood and subsequently less well considered in terms of budget and capital planning.

It is therefore crucial to really understand the drivers and technical motivation behind the requirements to upgrade or to make other choices.

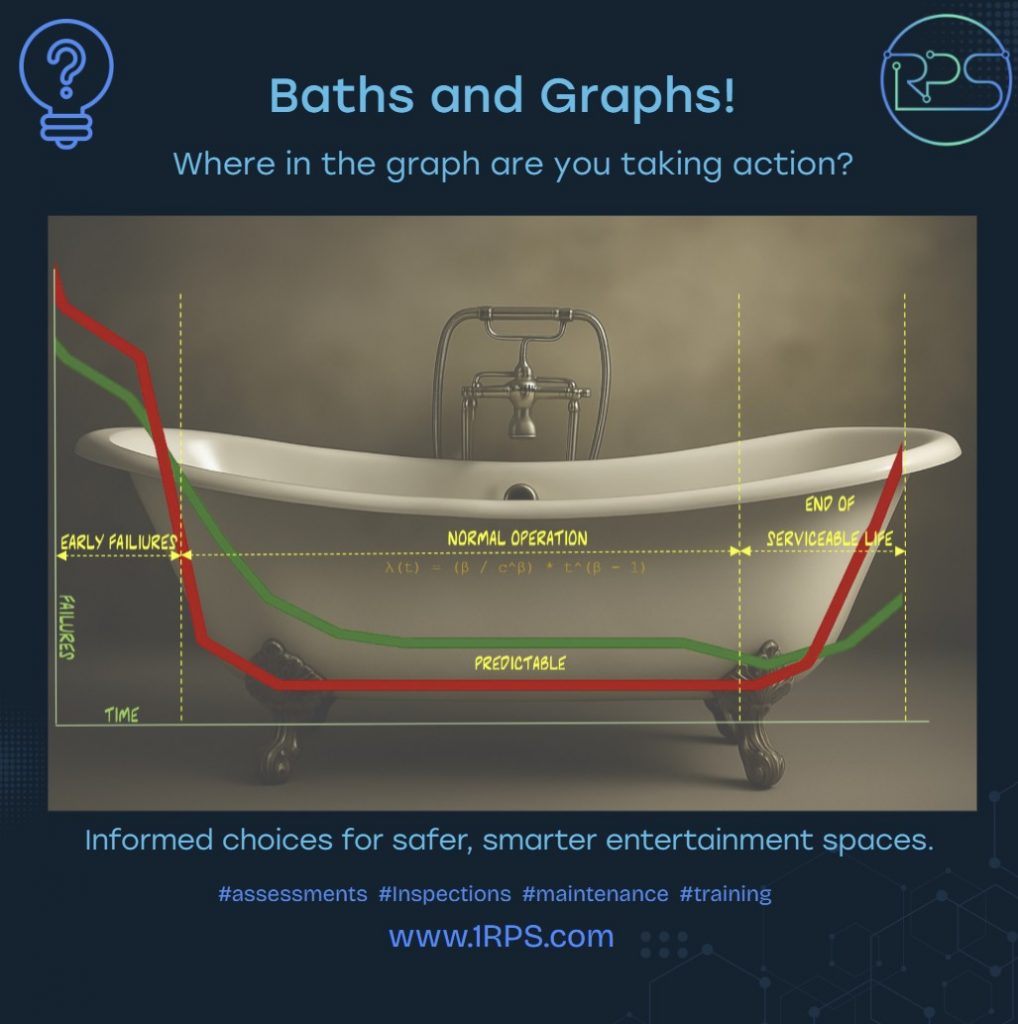

The Bathtub:

Every component in a system follows its own curve of life — think of the bathtub curve: early issues, a long steady run, then natural wear at the end. The trick is knowing where on that curve each part sits.

If we use the useful life generalisations of 5-7 years for Computers (Desks/Consoles/servers), 7-10 years for Drive systems and 10-15+ years for mechanical systems, then we have a good place to ensure we are inspecting, monitoring and logging correctly and hence are able to quantify age related failures.

Capacitors do have a life, hard drives do fail, and power supplies pop their fuses, ROM batteries lose their charge and bearings and lead screws do get worn, however with regular preventative maintenance and planned strategic interventions, these systems often significantly surpass their recommended useful life.

The next trick in line is to understand the failures; With good training an end user will be able to describe the difference between a drive failure vs a power issue, a brake checkback sensor fail vs a seized brake and a hard drive reliability issue vs a patch lead failure on a comms system.The next trick in line is to understand the failures; With good training an end user will be able to describe the difference between a drive failure vs a power issue, a brake checkback sensor fail vs a seized brake and a hard drive reliability issue vs a patch lead failure on a comms system.

So then, what does upgrade really mean?

A well-planned upgrade is most usefully and most often a planned, budgeted and phased intervention, replacement and refurbish plan.

Manufacturers will use a set out of rules to establish their systems supported life. These rules derive in fact from the component manufacturers own rules. For example, a Variable frequency drive from a major manufacturer will have a production life, a fully supported extended life, then drift into a world of supported, parts only, then eventually unsupported.

A system manufacturer using an array of these components will then base their own systems supported life span on a combination of all the components and indeed their own skill base. It is tricky and expensive to support multiple legacies of old systems with parts supply and expert knowledge.

At RPS we have decades of experience of supporting current and legacy systems across vendors and have a range of suppliers and experts supporting us with legacy skills and knowledge.

There are of course times when new equipment is required, most often it starts with the Desk or Console. This is the most obvious entry point into any system and since it is computer based, can suffer from inefficiencies of age and unreliability.

It is, of course worth considering that a Control Desk is mostly a reflection of the system behind it and that its function, if well specified, is to provide the User with the functionality and information they require to run the system reliably and safely.

If the functional requirements of the system have not changed, then we do not need to add complexity or functionality. If we only need simple, then keep it simple.

Greater functionality may be required in some cases and in for these, then the higher end Front End controls are appropriate and more efficient or refined functionalities may well be recommended.

The Drive system is in basic terms, a series of Amplifiers and are the least considered part of any system, however the most likely part of any system to require upgrade or replacement.

Drives rely on high power capacitors and components that over time can become problematic and are often bought from a small number of global manufacturers. Whilst these drives do become obsolete and manufacturer’s change frame sizes and connector types, it is a relatively easy mission to replace drives alone, with most modern control systems able to control almost any brand or type of drive.

PLCs and Position controllers are the brain of an Automation systems and are essentially extremely focused computers, running complex logic systems and creating the If this then that reactions of the system. Most PLCs used in Automation systems are industrial based devices, designed to run factories day in and day out for many years. Their focused nature and designed for task build leads them to be hugely reliable and fairly bullet proof.

Mechanical systems can be considered as serviceable parts in a systems, whether by End User or trained engineers. Maintenance, servicing and planned replacement of wearable parts can lead us to very long useable lives. Issues will often occur in cable management, dirt and debris in mechanics or lack of utilisations.

Therefore, an upgrade can be a wholesale swap of everything or most likely a control level upgrade or even simply a Control Desk change.

Does the system do what we need it to do?

The first test of any upgrade is utility, not novelty. Many systems still perform their intended function perfectly, even if their interfaces look dated or parts are harder to source. The key question isn’t “Is it old?” but “Is it limiting operations, safety, or compliance today?” Evidence beats instinct.

What is really driving the desire to upgrade?

Drivers often hide behind respectable labels like obsolescence or reliability. Sometimes it’s genuine — parts unavailable, safety standards changed, system no longer supported. But sometimes it’s cultural: new management, reputation, the illusion of progress. A true driver can be measured in downtime, cost of spares, or performance loss — not just in aesthetics or age.

Am I adding or reducing risk?

Upgrades can do both. New systems carry commissioning and integration risks, training gaps, and unfamiliar failure modes. Keeping an older system may carry mechanical or supply-chain risk. The balance sits in understanding which risks are known, controllable, and economically justified. Replacing known behaviour with unknown behaviour isn’t automatically safer.

Does the system need new functionality or are we adding complexity?

More capability is only an upgrade if it’s needed and understood. Extra layers of automation, networking, and diagnostics can become new single points of failure if they outstrip user competence or maintenance scope. Clarity of function should lead; technology should follow.

Am I spending capital to save on operational budget?

That can be sound — if you have the data to prove it. Predictive maintenance, power efficiency, or reduced man-hours are valid ROI levers, but only if measured against realistic life-cycle costs. If capex is being used to mask poor operational discipline, the saving will vanish quickly.

Is this perception or measurable technical reality?

Perception is powerful — a system that feels old can be treated as such, regardless of performance. The test is evidence: logged faults and data, component support timelines, inspection findings. If the argument for change can’t be expressed in numbers or risk metrics, it’s probably sentiment.

Could training, better understanding, strategic interventions and regular maintenance and inspections achieve the same outcome with less cost and risk?

Often, yes. Many “upgrades” conversations dissolve once operators fully understand the system’s behaviour, limitations, and maintenance intervals. Training and strategic interventions can stretch lifespan and reliability dramatically.

Is my system compliant?

A legacy system would have been designed to the standards of the day and does not need to be measured against current standards, unless a significant change is made. However operational processes do need to be current and need to consider any shortfall in legacy system standards. An upgrade often marks a significant change to a system and hence the requirements to be reassessed to current standards – this can open the door to an array of unexpected costs and complications.

What Options do I have?

It can be tempting to stay with the familiar — to accept the shortfalls, costs, and constraints that often come with larger, established brands. But automation technology has matured. Today, it’s entirely possible to assemble systems from multiple sources, selecting components that best serve your specific use cases and operational needs, much like how modern lighting systems mix fixtures and control from different manufacturers. With the right guidance, upgrades no longer have to mean full-scale replacement or vendor lock-in. The real choice lies between supplier-driven wholesale upgrades — often shaped by their sales cycles rather than your needs — and strategic interventions: phased, evidence-led replacements that reduce downtime, spread costs sensibly, and ensure your system evolves on your terms.

Summary:

Upgrades are not simply acts of replacement; they’re choices about direction. The right path isn’t always the newest or the most expensive, but the one that keeps the system purposeful, safe, and sustainable. Technology now gives us freedom — to adapt, to blend, to refine — rather than to start over. The question is no longer can it be upgraded? but how intelligently can it evolve?

Speak with RPS to understand the real condition of your system — and the choices that truly make sense.