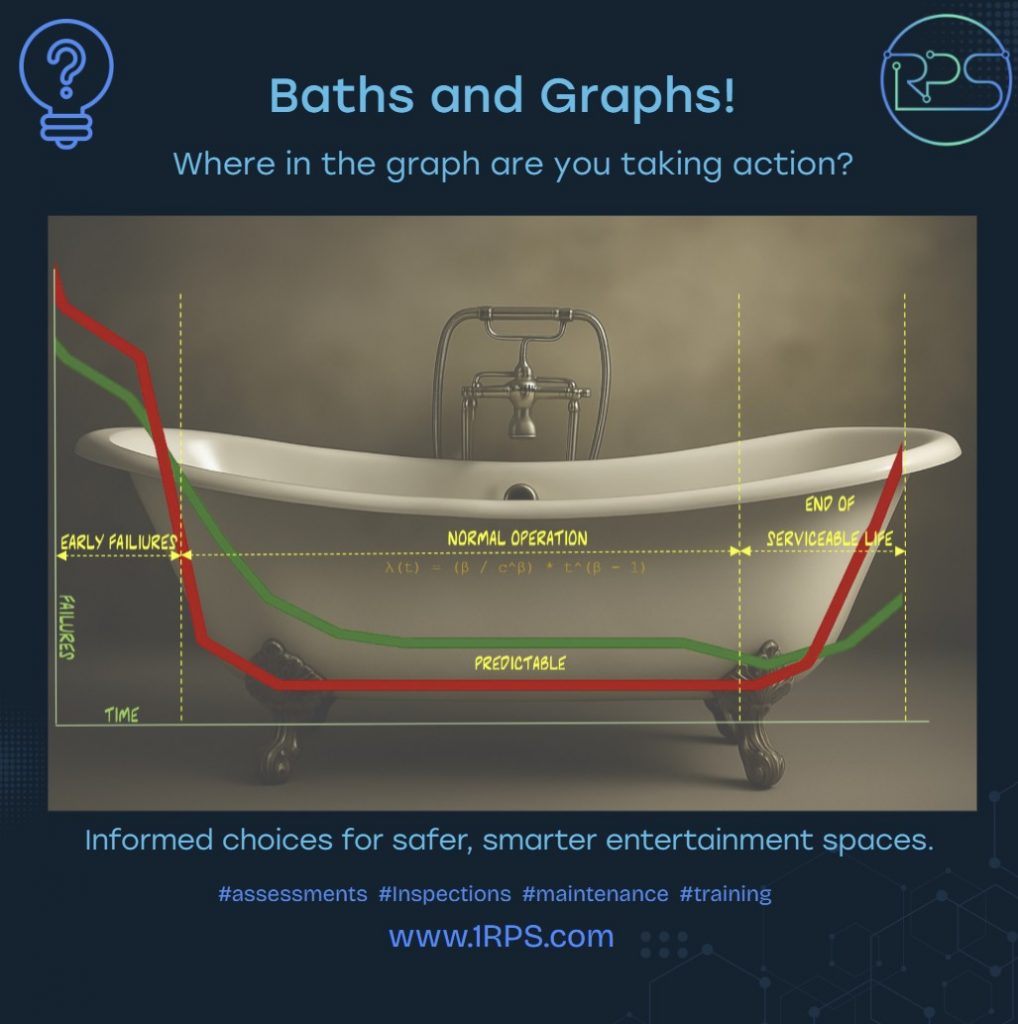

Understanding the Bathtub Curve

The bathtub curve is a simple but powerful way to describe how components typically fail over time and how predictable these failures can be.

- Early failures often appear soon after installation, linked to manufacturing issues, setup errors, or unforeseen stresses.

- Useful life is the long, stable period where failure rates remain low and predictable.

- Wear-out failures occur as parts age, materials fatigue, and obsolescence creeps in—causing failure rates to rise again.

What’s important is that each component in a system can sit at a different point on this curve. Some may be entering wear-out while others are still in their stable phase. That’s why treating a system as a single “all or nothing” upgrade often misses smarter, more strategic interventions.

An Automation system contains an array of electrical and mechanical components, each with varying life cycles and end of life cycles. Preventative maintenance and strategic replacements can significantly improve the reliability and predictability of a system as a whole.

Talk to Us

RPS can help assess where your equipment sits on the curve and plan preventative maintenance or targeted upgrades before issues escalate.

📩 Get in touch — we’d love to chat through tailored assessments for your venue or system.